The Worldly Product Impact Calculator

Methodology

Last update: August 2024

This document is WORLDLY CONFIDENTIAL. WORLDLY employees may share the link to this document directly with external parties.

Purpose

The purpose of this document is to describe the methodology of the Worldly Product Impact Calculator (PIC).

Product Impact Calculator Overview

The Product Impact Calculator methodology is built on materials and product data from industry aligned databases, including the Higg MSI and Higg Product Module. The methodology is aligned with the Greenhouse Gas Protocol Technical Guidance for Calculating Scope 3 Emissions and has been independently validated in accordance with ISO 14064-3.

Default product impact models are provided across 38 product categories, which can be further customized based on how much information is known about the product, allowing the user to move from the average-data method to the hybrid method, where it is relevant and material. Impacts per product are connected to purchase orders to calculate overall quantity of CO2e emissions (carbon dioxide equivalents). The Life Cycle Impact Assessment (LCIA) method used is IPCC AR6 GWP 100, the latest emission factor guidance delivered by IPCC.

The Product Impact Calculator includes Scope 3:

- Category 1 - Purchased Goods, which includes production of Materials, Packaging, Components, and Final Assembly impacts

- Category 4 - Upstream Transportation and Distribution

- Category 9 - Downstream Transportation and Distribution

- Category 11 - Use of Sold Products

- Category 12 - End of Life (Product and Packaging)

The basic version of our model uses the average-data method for calculating Scope 3, Category 1 as described in the Scope 3 Calculation Guidance.1 Within the tool, we also give users the ability to move to a blended approach that substitutes generic data for primary data (moving them to the hybrid data method) for the Scope 3 Category 1 inputs that are described in detail below.

The Product Impact Calculator includes 230 default product impact models across 38 product categories (see Appendix A). These default product impact models are built from a library of 33 industry average materials, 28 components, and 27 packaging options that is available for all tool users. Users can also select the product category “other” to model product impacts outside of the category options in the tool. Users have the option to expand their libraries by linking data from the Higg Materials Sustainability Index (MSI) and Product Module (PM). As will be described below, the Worldly team used the best available data to model these materials and products.

To go from product-level impacts to Scope 3 outputs, tool users connect products to Purchase Orders (POs) and dates. The linking of products, POs, and dates, enables us to allocate the emissions.

The equation is:

Total Impactstime = ∑ (Product Impactsproduct * Unitsproduct)

| Where | |

| Total Impactstime | All impacts calculated by the tool for the products made during a specific timeframe. |

| Product Impactsproduct | The overall impact calculated for each unique product modeled in the tool during that timeframe. |

| Unitsproduct | The number of units purchased of each product included within that timeframe. |

Every subsequent section of this methodology is focused on the product level, as product-level impacts are aggregated to arrive at the overall tool outputs. Impacts are calculated for a product every time a user adds a purchase order to a product in the Product Impact Calculator. Keeping impacts at the product-purchase order level improves the accuracy of our model outputs because: 1) some brands manufacture a SKU in multiple facilities that change across POs; and 2) the higher resolution data available from the Worldly Facility Data Manager (FDM) will be able to more closely connect when the PO is created to the impacts from a facility.

The Foundational Materials, Component, and Packaging Options

The key inputs to the default product impact models are the materials and components used in the 38 generic products. To build these products, we developed a collection of 33 generic materials, 28 components, and 27 packaging options. All 88 of these were modeled in the Higg Material Sustainability Index (MSI) with LCA for Experts (formally known as GaBi) serving as the background LCA database (Professional database and extension databases). The MSI methodology is publicly available.2

Materials

The set of materials included in the library was based on Textile Exchange’s Preferred Fiber & Materials Market Report (PFMMR)3 and the Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector4 working paper from the World Resources Institute and Apparel Impact Institute. The Higg MSI was used to model all three types of representative materials:

- Custom materials - that represent industry averages as defined in the Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector5 working paper;

- Example materials - from the Higg MSI (with an additional heat setting step added); and

- Blended materials - based on the expertise and insights of the Worldly team.

Overall, the list also includes non-fiber materials relevant to apparel companies (e.g. aluminum, leather, brass). We arrived at the following materials set:

| Acetate | Fleece | Nylon, Recycled |

| Acrylic | Foam, Polyethylene (PE) | Plastic, Polyethylene (PE) |

| Aluminum | Hemp | Polyester |

| Brass | Leather | Polyester (Insulation) |

| Canvas | Leather, Synthetic | Polyester, Recycled |

| Cotton | Linen/ Flax | Polypropylene |

| Cotton, Organic | Lyocell | Satin, Synthetic |

| Denim | Microfiber | Silk |

| Duck Down | Modal | Steel |

| Elastane/ Spandex | Nylon | Viscose/ Rayon |

| Fiberglass | Nylon (Outdoor) | Wool |

The materials are meant to reflect an industry average of textile processes. At times, this means that the representative materials are a mix of yarn and textile formation methods that may never be used in the same material in the real world. Because the tool uses representative blends, the impacts for these materials will not exactly match the materials used by brands. Rather, by providing an industry-weighted average, the Product Impact Calculator provides users with a directionally correct starting point. Product Impact Calculator users are encouraged to replace these representative materials with more customized ones that they have modeled in the Higg MSI (additional details are provided in Appendix B).

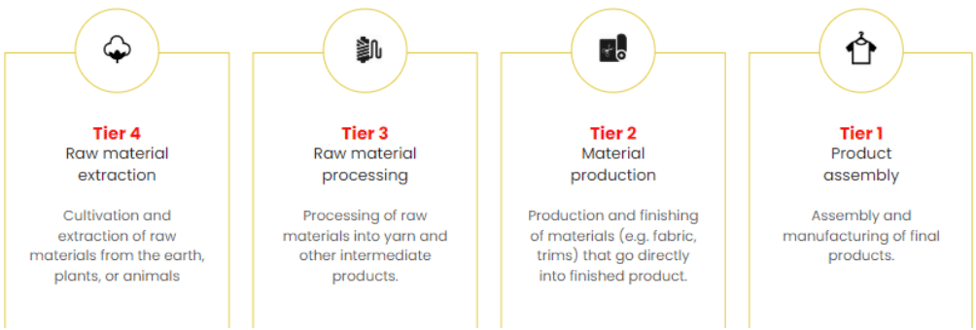

The impacts for materials come from Tier 4, (Raw Material Extraction), Tier 3 (Raw Material Processing), Tier 2 (Material Production) and the transportation between those tiers of the supply chain. The inputs, assumptions, and data sources for every material is available to users within the Product Impact Calculator.

Figure 1 - Illustration of the Product Impact Calculator material value chain

Source: Roadmap to Net Zero (World Resource Institute and Apparel Impact Institute)6

For each tier, the Product Impact Calculator model includes the loss rate7 associated with each step. The loss rate is the percentage of the input from the previous stage or step that is considered waste as part of the process. For example, a 5% loss rate means that for every 1 kg of input, there are 0.95 kg of product output (1 - 0.05 = 0.95). The impacts also include the transportation impacts for moving the material along the supply chain as well as the impacts associated with treating the waste from manufacturing. For transportation, we assume a distance of 200 km traveled by a large truck between each tier of the material supply chain. For transportation from the finalization of the material (Tier 2) to the Manufacturing and Final Assembly (Tier 1), we model a 500 km truck trip; the relevant portion of carbon emissions from this trip are allocated to the material life cycle stage. All default transportation values are taken from the Higg Index Product Module methodology8 (see Appendix C for additional transportation modeling specifics). A few examples will help bring this process into focus. Users can use the product library defaults or if more details are available (like specific manufacturing processes) they can alter the defaults to better match their product.

Users can use the default product impact models or, if more details are available (like specific manufacturing processes), they can create custom materials in MSI which will automatically be made available in the Product Impact Calculator. Here are the details on how two of the materials options were modeled.

Conventional Cotton

To arrive at the conventional cotton in the materials library, we applied the yarn and textile formation estimates provided in Roadmap to Zero9(yarn: 75% ring spun, 25% open ended; textile: 40% knit, 60% woven). To arrive at this mix, four materials were modeled and amalgamated in the Higg MSI:

| Name | Yarn formation | Textile formation | % of Industry Average Blend |

|---|---|---|---|

| Cotton (conventional), ring spun, knit | 75% | 40% | 30% |

| Cotton (conventional), ring spun, woven | 75% | 60% | 45% |

| Cotton (conventional), open end, knit | 25% | 40% | 10% |

| Cotton (conventional), open end, woven | 25% | 60% | 15% |

| Cotton (conventional) industry average | - | - | 100% |

Industry-standard loss rates were applied (available in Roadmap to Zero10) to model the impact of the amalgamated material.

Denim

The inputs for the Product Impact Calculator’s denim were based on the expertise and experience of the Worldly sustainability science team. While there are many ways to manufacture denim, the following is meant to represent an industry average. The stages and processes included are:

| Name | Loss Rate | Inbound Transp. Distance |

|---|---|---|

| Cotton fiber, conventional production | 0% | 0 km |

| Spinning, cotton, for woven, open end (rotor) (370 DTEX-333 denier-16/1 Ne-27 Nm) | 17.9% | 200 km |

| Weaving, 370 DTEX-333 denier-16/1 Ne-27 Nm | 2.5% | 200 km |

| Preparation for dye (scouring, etc), woven textile, natural fibers | 2% | 200 km |

| Batch dyeing (incl. piece, jet, jig, kier (fiber), paddle, yarn) - Direct, sulfur, vat or reactive dyes | 8% | 200 km |

| Heat setting, textiles, finishing | 1% | 200 km |

Components

The Product Impact Calculator includes 28 default components from the Higg MSI. Within the PIC, the number of components included in a product can be altered, but the weight and composition of those components cannot be changed (these customizations need to be made in the MSI tool). A default cutting efficiency of 75% and 1% defect rate 11 are applied from MSI. The table below shows what types of components are available in the tool. For a full list of the 28 components, see Appendix D.

| Button | Stoppers/ Endings |

| Buckle | Zipper/ Chain and Puller |

| Care Label | Zipper/ Chain |

| Shoelaces | Zipper/ Puller |

Packaging

The Product Impact Calculator includes 27 default packaging materials from the Higg MSI. The logic for components applies to packaging as well. All packaging calculations in the tool are on a per unit of product basis. A default cutting efficiency of 75% and 1% defect rate12 are applied from MSI. Users can further customize the packaging, including materials, weights, and cutting efficiency in the MSI tool. The table below shows what types of packaging are available in the tool. For a full list of the 27 packaging options, see Appendix E.

| Bag | Garment cover | Shoebox rope |

| Box | Hanger | Tissue paper |

| Bubble wrap | Hang tag | Toe stuffing |

| Foot form | Shoe sticks |

The default packaging type is a Bag (e-commerce/shipping) without a tertiary package (e.g. outer carton). Users who want to add or change the default packaging can select from the set of 27 types of packaging that come with the Product Impact Calculator. Total packaging impacts per product are equal to the sum of all packaging impacts used per product.

The net product weight includes the weight of packaging for all transportation from the gate to product end-of-life. The weight of the packaging is removed from the overall weight when calculating impacts from product use phase. Disposal of packaging is accounted for at the product end of life stage.

Scope 3, Category 1 – Purchased Goods and Services

We start by calculating cradle-to-gate impacts for Scope 3, Category 1 Purchased Goods and Services for each product (BOM = Bill of Materials). Within the text below, we start with the equations, define the variables, and then provide more information in paragraph form. In addition, we describe the average-data method and provide examples for how users can adjust this data or replace it with primary data to increase model accuracy and move into the hybrid method.

We define Scope 3, Category 1 Purchased Goods for each product as

Purchased Goodspack = ∑ (BOMmat + BOMcomp + Productpack + Final Assembly)

| Where | |

| BOMmat | ∑ = (Material EF) * (Gross Material Weight) * (% Material in BoM) |

| BOMcomp | ∑ = (Component EF) * (No. Components per Product) |

| Productpack | ∑ = (Packaging EF) * (No. Packaging per Product) |

| Final Assembly | [(Assembly EF) * (Product Net Weight)] + (EOL Impacts of Materials Net Loss) |

| And | |

| BOMmat | The impact to manufacture and transport all materials from the raw materials stage to the final assembly facility. We assume a 200km truck trip between each stage of the supply chain. The model also accounts for loss rates between each material processing stage (usually 5%). |

| BOMcomp | The impact to produce all of the components (e.g. zippers) and trims included in a product BOM. |

| Productpack | The impact of the primary packaging for the product. |

| Final Assembly | The impact of the final cut-and-sew processing that occurs in apparel manufacturing. |

BOMmat - these impacts include raw materials through material creation (i.e. the output is a finished fabric). It also includes the transport between stages, which is modeled as a 200km13 trip by large truck. These impact values cannot be altered in the Product Impact Calculator, but are editable by users in the MSI when creating custom materials.

For each product, the impact of the materials is the summation of the impact of each material multiplied by material weight. The material weight considers the net use (i.e. amount of material that was lost during final assembly). A default 75% net use is applied based on our understanding of the apparel industry; users can update the net use percentage to better match the efficiency of their product designs. The material weight is then prorated based on the percent of the product it represents. Additional details on the processes used to model each material in the Higg MSI using the LCA for Experts software and database14 were described in the materials section above.

BOMcomp – these refer to things beyond materials used in a product such as buttons, zippers, or labels. All Product Impact Calculator components were originally modeled within MSI and put into the Scope 3 library. Within MSI, the components were modeled to include loss rates, net use, and transportation between stages using the MSI material defaults. Default net use is 75% and the defect rate is 1%. Components are created on a unit basis and include the weight in kg for the Component. An example is a zipper-puller that is made of 0.004 kg of brass material.

The impact calculations for BOMcomp is the Component emission factor multiplied by the number of units of each component used in the product.

Productpack includes primary packaging by default; and users can add additional primary and secondary packaging. All Product Impact Calculator packaging options were originally modeled within MSI and put into the Scope 3 library. Within MSI, the packaging was modeled to include loss rates, net use, and transportation between stages. Packaging is created on a unit basis and includes the material weight. An example is a Small Paper Bag which is made of 0.034 kg paper.

The impact calculations for Productpack is the Packaging emission factor multiplied by the number of units of each Packaging used in the product.

Final Assembly – there are two approaches: default final assembly impacts and linked Tier 1 facility impacts. Final assembly is calculated by product for each purchase order. A product can have multiple purchase orders with different final assembly options (e.g. one purchase order can use a default assembly option, whereas a second for the product could use Facility XYZ and third purchase order could use Facility ABC).

The default final assembly finished goods manufacturing impacts (Tier 1) were calculated using a standard emission factor per kilogram of finished product that comes from the World Apparel Life Cycle Database and used in Roadmap to Net Zero report.15 This impact (1.83 kg CO2e/kg of product) uses a global electricity mix that represents the top apparel producing countries and includes electricity consumption (80 percent of the GHG impact of final assembly), thermal energy, and minor sources such as tap water. The Final Assembly includes a default transportation leg of 500km by large truck from the Tier 2 facility to the Tier 1 facility.16 The final assembly impact also includes impacts from end of life for all of the material that was lost as scrap during the process of making the final product.

In the facility linked option, users can update the final assembly impacts by connecting a product’s purchase to a specific Higg Facility Environmental Module (FEM) that has been shared with the brand. The FEM includes self-reported and optionally third-party verified total annual energy usage by energy source and reported annual production units for the facility. The linking capability allows users to replace the default Final Assembly per unit impact with primary data from the FEM where the product was manufactured. If multiple facilities are used, multiple purchase orders can be created to link to different FEMs. In 2022 and prior, facilities report their production volumes in a variety of units including piece/pair and kg. GHG emissions are normalized by dividing the facility total annual emissions by the reported annual production volume. In FEM 2023, production units are standard based on facility type; Final Product Assembly facilities report in pieces/pairs and all other facility types must report in kilograms. When linking a FEM 2023, only Final Product Assembly and/or Finished Product Processing can be linked to the Product Impact Calculator for Tier 1. The normalized GHG emissions of the facility replace the default in the calculation.

If there is no linked FEM, the default apparel assembly assumptions are used. In addition, the Worldly team is actively working on linking the data collected in the Facility Data Manager (FDM).17 The data from FDM will be compatible with the data collected in the FEM, but done on shorter time durations (e.g. monthly), which will allow for a more accurate allocation of facility emissions to each product produced. The Worldly team will also update the Tier 1 data options over time if new default product impact models with much different average Tier 1 impacts that apparel are added to the PIC.

Scope 3, Category 4 – Upstream Logistics

We define Scope 3, Category 4 Upstream Logistics as:

Upstream Transport = ∑(Ocean + Truck + Air) * (% Up Transport Unowned)

| Ocean | (Ocean EFkg * Oceandistance * Net Product Weight) |

| Truck | (Truck EFkg * Truckdistance * Net Product Weight) |

| Air | (Air EFkg * Airdistance * Net Product Weight) |

| Where | |

| Ocean EF | Emissions per kilogram per kilometer (kgkm) |

| Truck EF | Emissions per kilogram per kilometer (kgkm) |

| Air EF | Emissions per kilogram per kilometer (kgkm) |

| Net Product Weight | Weight of the final product materials and components plus the packaging weight. |

| % Upstream Transport Unowned | % of transport not owned by the company that is therefore included in Scope 3 (the owned part is included in Scope 1) |

| And | |

|---|---|

| Ocean EF | Emissions per kilogram per kilometer (kgkm) |

| Truck EF | Emissions per kilogram per kilometer (kgkm) |

| Air EF | Emissions per kilogram per kilometer (kgkm) |

| Net Product Weight | Weight of the final product materials and components plus the packaging weight. |

| % Upstream Transport Unowned | % of transport not owned by the company that is therefore included in Scope 3 (the owned part is included in Scope 1) |

Upstream logistics incorporates the distance a product travels from the final assembly (gate) to the distribution center. We assume that every product travels across a mix of ocean (14,850 km), truck (1,000 km), and air (1,750 km) to arrive at the distribution center. These transport impacts are multiplied by the net product weight (materials, components, and packaging) to arrive at the overall per product unit transportation impact. This aggregated number is then allocated to Scope 3 based on the percentage of the transport that is included in unowned third party. Our default assumption is that 100% of this Upstream transportation takes place in third-party transportation assets. Users can update this percent owned value for upstream logistics at the brand level. Users can also change the percentage assigned through brand-owned and third-party distribution networks at the brand level.

The transportation modality and distance blend required to get the product to the distribution centers come from a prior draft Apparel and Footwear Product Environmental Footprinting Category Rules (PEFCR) for the Apparel and Footwear industries. The transportation values modeled are:

| Transportation Modality | Final Assembly to Distribution Center Distances (km) | Total GHG per kg Product (in kgCO2e) |

|---|---|---|

| Ocean | 14,850 | 0.064 |

| Truck | 1,000 | 0.067 |

| Air | 1,750 | 1.07 |

| TOTAL | 17,600 | 1.2 |

Scope 3, Category 9 – Downstream Transportation and Logistics

The Downstream Transportation and Logistics calculation has two parts: 1) transportation from the distribution center to a retail store or e-commerce customer; and 2) the electricity and natural gas required to operate distribution centers and retail stores. We define Scope 3, Category 9 Downstream Transportation and Logistics as

Downstream Logistics = ∑ (Downtransport + Downdc + Downretail)

| Where | |

| Down transport | Downstream Transport EFunit * (Product Net Weight * % Transport Unowned) |

| Downdc | DC Emission Factorunit * (% Distribution Centers Unowned) |

| Downretail | (Retail Store Emission Factorunit) * (% of Retail Unowned) |

| And | |

| Downtransport | The impact of transporting the product from the Distribution Center to the Retail Store or e-commerce customer. This is calculated based on the net weight of each product and the percentage of transportation assets not owned by the brand, as those would be included in Scope 1. |

| Downdc | The percentage of emissions from running the distribution center allocated to each unit. |

| Downretail | The percentage of emissions from running the retail stores allocated to each unit. |

| Net Product Weight | The weight of the final product materials and components plus the packaging weight. |

Downtransport is the per kilogram emissions from transporting the product from the distribution center to the Retail Store of e-commerce customer multiplied by the product net weight (materials, packaging, and components) in kilograms to arrive at the overall per product unit transportation impact. The default distance and modalities for retail and ecommerce transportation are 1,000 km and large truck, respectively. The Global Warming Potential is calculated per kgkm. Like with upstream transportation, a percent ownership is applied to the total impacts to avoid applying Scope 1 impacts to the Scope 3 logistics.19 Our default assumption is that 50% of this Downstream transportation takes place in third-party transportation assets. Users can update this percent owned value for downstream logistics in the tool. Retail Center to Consumer transport (i.e. consumer driving from the retail store to their home) and any transportation related to returns are excluded.

| Variable | Unit | Source |

|---|---|---|

| Transportation impact | Per 1 kgkm | EU-28: Transport, truck-trailer (40 t total cap., 24.7 t payload) |

Downdc is the impacts allocated to each unit related to the impacts of running a distribution center. They are calculated on a per product unit basis by multiplying the default electricity and natural gas usage by the default global emissions factors that is based on a global electricity mix put together by Cascale (formerly the Sustainability Apparel Coalition). The per product unit emissions from distribution center electricity (0.065 kWh per unit) and natural gas (0.215 kWh) consumption are fixed and drawn from the most recent updates to the Higg Product Module; they were initially created using data and expertise from Cascale members. A global electricity mix based on domestic consumption was used to represent the emission factors for distribution center locations. The distribution center impacts are then allocated to Scope 3 based on the percentage of the Distribution Center work that occurs in unowned third party facilities. Our default assumption is that 50% of this Distribution Center impact takes place in third-party assets. Users can update this percent owned value for the distribution center in the Product Impact Calculator.

Downretail impacts are calculated on a per product unit basis. Impacts are calculated by multiplying the electricity used (0.75 kWh per unit) by the relevant emissions factor. A global electricity mix based on domestic consumption was used to represent the emission factors for retail locations.20 The per unit emissions from retail stores is fixed and drawn from the Higg Product Module; they were initially created using data and expertise from Cascale members. All products are considered one unit; the weight or size of each product is not reflected in this default. The Retail impacts are then allocated to Scope 3 based on the percentage of the retail that occurs is unowned third party retail stores (e.g. a multi-brand retail store. Our default assumption is that 50% of this Retail takes place in third-party stores. Users can update this percent owned value for retail stores in the Product Impact Calculator.

Electricity and natural gas consumption are the two inputs to the emissions from Distribution Centers and Retail stores.21 The per unit impacts are:

| Electricity (kWh) | Natural Gas (kWh) | |

|---|---|---|

| Distribution Center | 0.065 | 0.215 |

| Retail | 0.75 | 0 |

Scope 3, Category 11 – Use of Sold Products

We define Scope 3, Category 11 Use of Sold Products as:

Product UseImpacts= (Net Product Weight) * (Lifetime Washes) * (Washing EF)

| Where | |

| Net Product Weight | The weight of the final product materials and components plus the packaging weight. |

| Lifetime Washes | The number of total expected wears divided by the number of times worn between each washing. |

| Washing EF | The emissions associated with each kg of clothing laundered. |

The per unit use phase impacts are calculated by dividing the total expected number of lifetime uses (wears) by the numbers of times worn between each cleaning. This provides the total number of times that the product will be cleaned. The number of cleanings is then multiplied by the sum of the impacts of cleaning the product. These total product lifetime cleaning impacts are then multiplied by the net weight of the product, as the allocation of impacts from washing and/or drying a product is done on a weight basis. The way in which a product is cleaned is based on the product type and some products (such as footwear) do not have any associated washing and care cycles. Details are provided in the Product Care section below and Appendix F.

The product category for the default product impact models is used to determine how often the product is washed and the type of care for the default fabric. The default material for all categories is cotton except for hosiery, for which the default material is synthetic. The default approach to drying for all categories is “Line/Air Dry” and “No Ironing.” Product weight is the key driver of product care impact; it is assumed that each load of laundry includes 4 kg of apparel, with impacts being allocated based on product weights. A subset of these assumptions is provided below.

| Product Category | Fabric Category | Standard Consumer Care Practice | Standard Use Frequency b/w Washes | Lifetime Uses |

|---|---|---|---|---|

| T-Shirt | Cotton | Machine Wash Warm, Line/Air Dry | 1.5 | 46 |

| Pants | Cotton | Machine Wash Warm, Line/Air Dry | 4.2 | 66 |

| Socks | Cotton | Machine Wash Warm, Line/Air Dry | 1.5 | 52.3 |

Scope 3, Category 12: End-of-Life Treatment of Sold Products

We define Scope 3, Category 12 End-of-Life (EOL) Treatment of Sold Products as:

Product EOLimpacts = (Net Product Weight) * (End of Life Emission Factor)

| Where | |

| Net Product Weight | The weight of the final product materials and components plus the packaging weight. |

| EOL Emission Factor | The emissions associated with the End-of-Life treatment of each kg of clothing. |

For each unit of a product, the end-of-life impact is calculated by multiplying the product net weight by the default final disposal impact per kg of product. The Final Disposal Impact is a blended impact for which we assume that 31.5% of products are sent to a municipal waste incineration plant, 63% are sent to a landfill, and the remaining 5.5% are recycled by consumers. As we are using the cut off approach for recycling, there is no environmental impact associated with product recycling.

| Variable | Value (kg CO2e) | Unit | Source |

|---|---|---|---|

| Disposal impact for materials at assembly stage | 0.961 | Per kg waste | 31.5%- Commercial waste in municipal waste incineration plant 63%- EU-28: Commercial waste (AT, DE, IT, LU, NL, SE, CH) on landfill 5.5%- Recycling |

Appendices

Appendix A: The 38 Product Categories

| Backpacks | Jackets, Lightweight | Skirts |

| Bags | Jeans | Sleeping Bags |

| Baseball Caps | Jumpsuits, Rompers | Socks |

| Belts | Overalls, Coveralls | Sweaters, Sweatshirts, Hoodies |

| Bras, Everyday | Pajamas, Bottom | Swimwear |

| Bras, Sports | Pajamas, Set | T-Shirts |

| Dresses, Casual | Pajamas, Top | Tank Tops |

| Dresses, Formal | Pants | Tents |

| Dresses, Lightweight | Rash Guards | Tights, Leggings, Yoga Pants |

| Gloves | Scarves | Underwear |

| Hats | Shirts, Button-Down | Vests |

| Jackets | Shirts, Polo | Wallets |

| Jackets, Down | Shorts |

Appendix B: Full Description of Materials in the Product Impact Calculator

| Material Name | Description/Assumptions for Yarn Types |

|---|---|

| Acetate | Industry average based on assumptions used in Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector (2021) -Raw material source: Acetylated and regenerated cellulose, from pine, spruce or cotton linters -Yarn formation: Ring spun; 200 dtex -Textile formation: 40% knit, 60% woven; 200 dtex -Preparation: Preparation for dye (scouring, etc), knit textile, natural fibers -Coloration: Batch dyeing (incl. piece, jet, jig, kier, yarn) - Disperse or cationic dyes -Additional coloration and finishing: Heat setting, textiles, finishing |

| Acrylic | Industry average based on assumptions used in Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector (2021) -Raw material source: Polyacrylonitrile, fossil fuel based -Yarn formation: 100% staple fiber ring spun; 200 dtex -Textile formation: 40% knit, 60% woven; 200 dtex -Preparation: Scouring, synthetic fibers -Coloration: Batch dyeing (incl. piece, jet, jig, kier [fiber], paddle, yarn) - Direct, sulfur, vat or reactive dyes -Additional coloration and finishing: Heat setting, textiles, finishing |

| Aluminum | Higg MSI Example Material: Aluminum |

| Brass | Higg MSI Example Material: Brass |

| Canvas | Custom material: -Raw material source: Cotton fiber, conventional production -Yarn formation: Spinning, cotton, for woven, open end (rotor) (370 DTEX-333 denier-16/1 Ne-27 Nm) -Textile formation: Weaving, 370 DTEX-333 denier-16/1 Ne-27 Nm -Preparation: Preparation for dye (scouring, etc), woven textile, natural fibers -Coloration: Batch dyeing (incl. piece, jet, jig, kier [fiber], paddle, yarn) - Direct, sulfur, vat or reactive dyes -Additional coloration and finishing: Heat setting, textiles, finishing |

| Cotton | Industry average based on assumptions used in Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector (2021) -Raw material source: Cotton fiber, conventional production -Yarn formation: 75% ring spun, 25% staple fiber rotor spun; 200 dtex -Textile formation: 40% knit (circular), 60% woven; 200 dtex -Preparation: Preparation for dye (scouring, etc.) -Coloration: Batch dyeing (incl. piece, jet, jig, kier [fiber], paddle, yarn) - Direct, sulfur, vat or reactive dyes -Additional coloration and finishing: Heat setting, textiles, finishing |

| Cotton, Organic | Industry average based on assumptions used in Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector (2021) -Raw material source: Cotton fiber, organic -Yarn formation: 75% ring spun, 25% staple fiber rotor spun; 200 dtex -Textile formation: 40% knit (circular), 60% woven; 200 dtex -Preparation: Preparation for dye (scouring, etc.) -Coloration: Batch dyeing (incl. piece, jet, jig, kier [fiber], paddle, yarn) - Direct, sulfur, vat or reactive dyes -Additional coloration and finishing: Heat setting, textiles, finishing |

| Denim | Custom material: -Raw material source: Cotton fiber, conventional production -Yarn formation: Spinning, cotton, for woven, open end (rotor) (370 DTEX-333 denier-16/1 Ne-27 Nm) -Textile formation: Weaving, 370 DTEX-333 denier-16/1 Ne-27 Nm -Preparation: Preparation for dye (scouring, etc), woven textile, natural fibers -Coloration: Batch dyeing (incl. piece, jet, jig, kier [fiber], paddle, yarn) - Direct, sulfur, vat or reactive dyes -Additional coloration and finishing: Heat setting, textiles, finishing |

| Duck Down | Higg MSI Example Material: Duck Down (Insulation) |

| Elastane/ Spandex | Industry average based on assumptions used in Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector (2021) -Raw material source: Spandex fiber {The LYCRA Company}, contains data for yarn formation/spinning -Yarn formation: Spinning, continuous filament -Textile formation: 40% knit, 60% woven; 200 dtex -Preparation: None -Coloration: Solution (dope) dyeing -Additional coloration and finishing: Heat setting, textiles, finishing |

| Fiberglass | Custom material: -Raw material source: 50% Glass fiber; 50% Epoxy plastic, fossil fuel based -Textile formation: Non-woven, dry laid -Molding/curing: Injection molding, for plastic -Additional coloration and finishing: Heat setting, textiles, finishing -Mixing/preparation: Master batch blending and compounding, plastics |

| Fleece | Custom material: -Raw material source: Polyethylene terephthalate (PET), fossil fuel based -Yarn formation: Extrusion and melt-spinning, continuous filament, with texturing (80 to 500 DTEX- 72 to 450 den-125 to 20 Nm) -Textile formation: Knitting, 200 DTEX-180 denier-30/1 Ne-50 Nm -Preparation: Scouring, synthetic fibers -Coloration: Batch dyeing (incl. piece, jet, jig, kier, yarn) - Disperse or cationic dyes -Additional coloration and finishing: (1) Brushing/buffing, for textiles; (2) Napping, mechanical; (3) Pad-Dry-Cure or Exhaust-Dry-Cure; (4) Heat setting, textiles, finishing |

| Foam, Polyethylene (PE) | Higg MSI Example Material: Foam, Polyethylene (PE) |

| Hemp | Industry average based on assumptions used in Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector (2021) -Raw material source: Hemp fiber, average production (long fiber for wet spinning) -Yarn formation: 100% bast fiber spun -Textile formation: 40% knit, 60% woven; 200 dtex -Preparation: Preparation for dye (scouring, etc) -Coloration: Batch dyeing (incl. piece, jet, jig, kier [fiber], paddle, yarn) - Direct, sulfur, vat or reactive dyes -Additional coloration and finishing: Heat setting, textiles, finishing |

| Leather | Higg MSI Example Material: Leather (Cow) |

| Leather, Synthetic | Higg MSI Example Material: Leather, Synthetic (Polyurethane) |

| Linen/ Flax | Industry average based on assumptions used in Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector (2021) -Raw material source: Flax fiber (linen), average production -Yarn formation: 100% bast fiber spun -Textile formation: 40% knit, 60% woven; 200 dtex -Preparation: Preparation for dye (scouring, etc) -Coloration: Batch dyeing (incl. piece, jet, jig, kier [fiber], paddle, yarn) - Direct, sulfur, vat or reactive dyes -Additional coloration and finishing: Heat setting, textiles, finishing |

| Lyocell | Industry average based on assumptions used in Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector (2021) -Raw material source: Lyocell (generic), regenerated cellulose from wood pulp -Yarn formation: 100% staple fiber ring spun; 200 dtex -Textile formation: 40% knit (circular), 60% woven; 200 dtex -Preparation: Preparation for dye (scouring, etc.) -Coloration: Batch dyeing (incl. piece, jet, jig, kier [fiber], paddle, yarn) - Direct, sulfur, vat or reactive dyes -Additional coloration and finishing: Heat setting, textiles, finishing |

| Microfiber | Custom material: -Raw material source: Polyethylene terephthalate (PET), fossil fuel based -Yarn formation: Spinning, microfibers (yarn size<1 dtex), for textiles -Textile formation: Knitting, 200 DTEX-180 denier-30/1 Ne-50 Nm -Preparation: Scouring, synthetic fibers -Coloration: Batch dyeing (incl. piece, jet, jig, kier, yarn) - Disperse or cationic dyes -Additional coloration and finishing: Heat setting, textiles, finishing |

| Modal | Industry average based on assumptions used in Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector (2021) -Raw material source: Modal (generic), regenerated cellulose from wood pulp -Yarn formation: 100% staple fiber ring spun; 200 dtex -Textile formation: 40% knit (circular), 60% woven; 200 dtex -Preparation: Preparation for dye (scouring, etc.) -Coloration: Batch dyeing (incl. piece, jet, jig, kier [fiber], paddle, yarn) - Direct, sulfur, vat or reactive dyes -Additional coloration and finishing: Heat setting, textiles, finishing |

| Nylon | Industry average based on assumptions used in Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector (2021) -Raw material source: Nylon 6, fossil fuel based -Yarn formation: 90% filament, 10% staple fiber ring spun -Textile formation: 40% knit, 60% woven; 200 dtex -Preparation: Scouring, synthetic fibers -Coloration: Batch dyeing (incl. piece, jet, jig, kier, yarn) - Disperse or cationic dyes -Additional coloration and finishing: Heat setting, textiles, finishing |

| Nylon (Outdoor) | Industry average based on assumptions used in Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector (2021) -Raw material source: Nylon 6, fossil fuel based -Yarn formation: 90% filament, 10% staple fiber ring spun -Textile formation: 40% knit, 60% woven; 70 dtex -Preparation: Scouring, synthetic fibers -Coloration: Batch dyeing (incl. piece, jet, jig, kier, yarn) - Disperse or cationic dyes -Additional coloration and finishing: Heat setting, textiles, finishing |

| Nylon, Recycled | Industry average based on assumptions used in Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector (2021) -Raw material source: Nylon, mechanically recycled, for textile -Yarn formation: 90% filament, 10% staple fiber ring spun -Textile formation: 40% knit, 60% woven; 200 dtex -Preparation: Scouring, synthetic fibers -Coloration: Batch dyeing (incl. piece, jet, jig, kier, yarn) - Disperse or cationic dyes -Additional coloration and finishing: Heat setting, textiles, finishing |

| Plastic, Polyethylene (PE) | Higg MSI Example Material: Plastic, Polyethylene (PE) |

| Polyester | Industry average based on assumptions used in Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector (2021) -Raw material source: PET, fossil fuel based -Yarn formation: 67% filament, 33% staple fiber ring spun; 200 dtex -Textile formation: 40% knit, 60% woven; 200 dtex -Preparation: Scouring, synthetic fibers -Coloration: Batch dyeing (incl. piece, jet, jig, kier, yarn) - Disperse or cationic dyes -Additional coloration and finishing: Heat setting, textiles, finishing |

| Polyester (Insulation) | Higg MSI Example Material: Polyester (Insulation) |

| Polyester, Recycled | Industry average based on assumptions used in Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector (2021) -Raw material source: Polyethylene terephthalate (PET), mechanically recycled, for textiles -Yarn formation: 67% filament, 33% staple fiber ring spun; 200 dtex -Textile formation: 40% knit, 60% woven; 200 dtex -Preparation: Scouring, synthetic fibers -Coloration: Batch dyeing (incl. piece, jet, jig, kier, yarn) - Disperse or cationic dyes -Additional coloration and finishing: Heat setting, textiles, finishing |

| Polypropylene | Industry average based on assumptions used in Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector (2021) -Raw material source: Isotactic polypropylene (PP), fossil fuel based -Yarn formation: 60% filament, 40% staple fiber ring spun; 200 dtex -Textile formation: 40% knit, 60% woven; 200 dtex -Preparation: Scouring, synthetic fibers -Coloration: Solution (dope) dyeing -Additional coloration and finishing: Heat setting, textiles, finishing |

| Satin, Synthetic | Custom material: -Raw material source: Polyethylene terephthalate (PET), fossil fuel based -Yarn formation: Extrusion and melt-spinning, continuous filament, no texturing (80 to 500 DTEX- 72 to 450 den- 125 to 20 Nm) -Textile formation: Weaving, 70 DTEX-63 denier-84/1 Ne-143 Nm -Preparation: Scouring, synthetic fibers -Coloration: Batch dyeing (incl. piece, jet, jig, kier, yarn) - Disperse or cationic dyes -Additional coloration and finishing: (1) Pad-Dry-Cure or Exhaust-Dry-Cure; (2) Heat setting, textiles, finishing |

| Silk | Industry average based on assumptions used in Roadmap to Net Zero: Deliverying Science-Based Targets in the Apparel Sector (2021) -Raw material source: Silk, raw, from silkworm -Yarn formation: Silk reeling (spinning) -Textile formation: 40% knit, 60% woven; 200 dtex -Preparation: Preparation for dye (scouring, etc.) -Coloration: Batch dyeing (incl. piece, jet, jig, kier [fiber], paddle, yarn) - Direct, sulfur, vat or reactive dyes -Additional coloration and finishing: Heat setting, textiles, finishing |

| Steel | Higg MSI Example Material: Steel |

| Viscose/ Rayon | Industry average based on assumptions used in Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector (2021) -Raw material source: Viscose/Rayon (generic), regenerated cellulose from wood pulp -Yarn formation: 100% staple fiber ring spun; 200 dtex -Textile formation: 40% knit (circular), 60% woven; 200 dtex -Preparation: Preparation for dye (scouring, etc.) -Coloration: Batch dyeing (incl. piece, jet, jig, kier [fiber], paddle, yarn) - Direct, sulfur, vat or reactive dyes -Additional coloration and finishing: Heat setting, textiles, finishing |

| Wool | Industry average based on assumptions used in Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector (2021) -Raw material source: Wool, from sheep, fine-medium and superfine, Australia, for textile -Yarn formation: 100% staple fiber ring spun; 200 dtex -Textile formation: 40% knit (circular), 60% woven; 200 dtex -Preparation: Scouring, natural fibers -Coloration: Batch dyeing (incl. piece, jet, jig, kier [fiber], paddle, yarn) - Direct, sulfur, vat or reactive dyes -Additional coloration and finishing: Heat setting, textiles, finishing |

Appendix C: Transportation Modeling Specifics

| Transportation Leg | Lifecycle Stage | Scope 3 Category | Modeling Assumptions |

| Between nodes in the supply chain from raw materials (Tier 4) to the completion of the material (Tier 2) | Materials | Scope 3, Category 1 - Purchased Goods and Services | The default value of 200km by large truck for each production stage. This cannot be updated in the Product Impact Calculator, but can be adjusted in the Higg MSI. |

| Transportation from material finalization location (Tier 2) to manufacturing final assembly (Tier 1) | Materials | Scope 3, Category 1 - Purchased Goods and Services | The default value is 500km by large truck for each material. This cannot be updated in the Product Impact Calculator, but can be adjusted in the Higg Product Module. |

| Transportation from manufacturing final assembly (Tier 1) to the distribution center. | Upstream Logistics | Scope 3, Category 4 - Upstream Transportation and Distribution | Default value of 14850km by ocean freight, 1000km by large truck, and 1750km by air freight. This assumption is from the draft Apparel and Footwear PEFCR. This is adjustable by the user if data is available |

| Transportation from distribution center to retail stores. | Downstream Transport and Distribution | Scope 3, Category 9 - Downstream Transportation and Distribution | The default value is 1000km by large truck for each material. This cannot be updated in the Product Impact Calculator, but can be adjusted in the Higg Product Module. In addition, we assume that 70% of products are transported from the distribution center to the retail stores in brand-owned assets. This means that only 30% of impacts from this transportation leg are allocated to Scope 3, Category 4; the impacts from the remaining 70% are not included in the Product Impact Calculator output. Product Impact Calculator users can change this weighting at the overall business level within the Higg Product Module settings. |

| Transportation direct from distribution center to customers. | Downstream Transport and Distribution | Scope 3, Category 9 - Downstream Transportation and Distribution | The default value is 1000km by large truck for each material. This cannot be updated in the Product Impact Calculator, but can be adjusted in the Higg Product Module. In addition, we assume that 70% of products are transported from the distribution center to the customer in brand-owned assets. This means that only 30% of impacts from this transportation leg are allocated to Scope 3, Category 4; the impacts from the remaining 70% are not included in the Product Impact Calculator output. Product Impact Calculator users can change this weighting at the overall business level within the Higg Product Module settings. |

Appendix D: Component options

| Component Name | Description |

|---|---|

| Button/ Snap Button, Aluminum (12mm) | 0.00183 kilogram aluminum; 75% cutting efficiency |

| Button/ Snap Button, Brass (12mm) | 0.00183 kilogram brass; 75% cutting efficiency |

| Button/ Snap Button, Nylon (12mm) | 0.00031 kilogram nylon/polyamide (PA) plastic; 75% cutting efficiency |

| Button/ Snap Button, Polyester (12mm) | 0.00031 kilogram polyester plastic; 75% cutting efficiency |

| Button/ Snap Button, Aluminum (25mm) | 0.01 kilogram aluminum; 75% cutting efficiency |

| Button/ Snap Button, Brass (25mm) | 0.01 kilogram brass; 75% cutting efficiency |

| Button/ Snap Button, Nylon (25mm) | 0.00183 kilogram nylon/Polyamide (PA) plastic; 75% cutting efficiency |

| Button/ Snap Button, Polyester (25mm) | 0.00183 kilogram polyester plastic; 75% cutting efficiency |

| Buckle/ Ring, PE | 0.001 kilogram polyethylene (PE) plastic; 75% cutting efficiency |

| Buckle/ Ring, Steel | 0.01 kilogram steel; 75% cutting efficiency |

| Label/ Care Label, PES | 0.0001 kilogram polyester plastic; 75% cutting efficiency |

| Label/ Care Label, Printed Fabric | 0.0007 kilogram polyester fabric; 75% cutting efficiency |

| Shoelaces, Polyester | 0.01 kilogram polyester fabric; 75% cutting efficiency |

| Shoelaces, Wool | 0.01 kilogram wool fabric; 75% cutting efficiency |

| Stoppers/ Endings, PP | 0.005 kilogram polypropylene (PP) plastic; 75% cutting efficiency |

| Stoppers/ Endings, Silicone | 0.005 kilogram silicone rubber; 75% cutting efficiency |

| Stoppers/ Endings, TPU | 0.005 kilogram Thermoplastic Polyurethane (TPU) plastic; 75% cutting efficiency |

| Label/ Care Label, Woven | 0.0005 kilogram polyester fabric; 75% cutting efficiency |

| Zipper/Chain and Puller, Aluminum (Short) | 0.005 kilogram aluminum; 75% cutting efficiency |

| Zipper/Chain and Puller, Brass (Short) | 0.005 kilogram brass; 75% cutting efficiency |

| Zipper/Chain and Puller, Nylon (Short) | 0.00083 kilogram nylon fabric; 75% cutting efficiency |

| Zipper/Chain, Aluminum (Short) | 0.004 kilogram aluminum; 75% cutting efficiency |

| Zipper/Chain, Brass (Short) | 0.004 kilogram brass; 75% cutting efficiency |

| Zipper/Chain, Nylon (Short) | 0.00066 kilogram nylon fabric; 75% cutting efficiency |

| Zipper/ Puller, Aluminum | 0.001 kilogram aluminum; 75% cutting efficiency |

| Zipper/ Puller, Brass | 0.001 kilogram brass; 75% cutting efficiency |

| Zipper/ Puller, Nylon | 0.00017 kilogram nylon fabric; 75% cutting efficiency |

| Zipper/Chain and Puller, Brass/ Nylon (Extra Long) | 0.088554876 kilogram brass; 75% cutting efficiency 0.002818091 kilogram polyester fabric; 75% cutting efficiency |

Appendix E: Packaging options

| Packaging Name | Description |

| Bag (E-Commerce/Shipping) |

|

| Box, Shipping |

|

| Box, Shoes (Men's) |

|

| Box, Shoes (Women's) |

|

| Box, Shoes (Youth) |

|

| Bubble Wrap |

|

| Foot Form (Pair) |

|

| Garment Cover (Short) |

|

| Hanger, Cardboard (Shoes) |

|

| Hanger, Polypropylene |

|

| Hanger, Polypropylene (Shoes) |

|

| Hanger, Polystyrene |

|

| Hanger, Steel |

|

| Hanger, Wood/Steel |

|

| Hanger, Wood/Steel (Pants) |

|

| Hangtag (Large) |

|

| Hangtag (Small) |

|

| Rope, Polyester (Box, Shoes) |

|

| Rope, Polypropylene (Box, Shoes) |

|

| Shoe Sticks (Pair) |

|

| Shopping Bag, Paper (Large) |

|

| Shopping Bag, Paper (Small) |

|

| Shopping Bag, Plastic (Large) |

|

| Shopping Bag, Plastic (Medium) |

|

| Shopping Bag, Plastic (Small) |

|

| Tissue Paper |

|

| Toe Stuffing (Pair) |

|

Appendix F: Washing Scenarios

Washing machine assumptions are included below. Product lifetimes and lifetime washes are sourced from Higg Index Product Module methodology.22 For simplicity, the Product Impact Calculator does not consider the fabric category, but defaults to the cotton care scenario for all products.

| Washing Scenarios | |||

|---|---|---|---|

| Washing temperature | Cold 20C (68F) | Warm 40C (104F) | Hot 60C (140F) |

| Load | 4kg | ||

| Energy consumption for normal washing cycle | 0.79 kWh/load | ||

| Energy for heating the water for the wash |

0 kWh 0 MJ NG |

0.979 kWh 5.129 MJ NG |

1.957 kWh 10.259 MJ NG |

| Water consumption | 9 L/load | ||

| Water Use | 70 L/load | ||

| Quantity of wastewater | 61 L/load | ||

- See Chapter 1, Purchased Goods and Services in Technical Guidance for Calculating Scope 3 Emissions (version 1.0) (PDF)↩︎

- Higg MSI Methodology (February, 2023) ↩︎

- These reports can be found at the following link: Preferred Fiber and Materials Market Report 2022 ↩︎

- The report can be found at the following link: Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector (PDF)↩︎

- Available at Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector (PDF) ↩︎

- Available at Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector (PDF)↩︎

- The loss rate assumptions come directly from the Higg MSI. Those loss rates were determined using “values from secondary data sources, expert guidance, and industry methodology such as Textile Exchange’s Fiber Conversion Methodology.” See the MSI methodology for additional detail: Higg Product Module (PM) Methodology (PDF)↩︎

- Methodology is available at the following Higg Product Module (PM) Methodology (PDF)↩︎

- Available at Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector (PDF) ↩︎

- Available at Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector (PDF)↩︎

- Creating Customized Trims/Components and Packaging ↩︎

- Creating Customized Trims/Components and Packaging ↩︎

- See Production Stage assumptions. Based on industry expertise. Higg MSI Methodology (February, 2023) ↩︎

- LCA for Experts (GaBi) ↩︎

- The report can be found at the following link: Roadmap to Net Zero: Delivering Science-Based Targets in the Apparel Sector (PDF) ↩︎

- See Logistics section Higg Product Module (PM) Methodology (PDF) ↩︎

- Enabling Supply Chain Transparency: Introducing Facility Data Manager ↩︎

- Environmental Footprint Methods - European Commission ↩︎

- A 50% ownership is assumed and applied, though tool users have the ability to alter this assumptions ↩︎

- See Retail section Higg Product Module (PM) Methodology (PDF) ↩︎

- See World Power consumption | Electricity consumption | Enerdata ↩︎

- Table 8: Product Care Scenarios. Higg Product Module (PM) Methodology (PDF) ↩︎